Once thought impossible, the era of ropeless, sideways-moving elevators is finally here. We have come a long way since the 138-foot Home Insurance building opened in Chicago in 1884 as the world’s first skyscraper. Not only did it herald the start of rapid urban population growth, but it also signaled the beginning of elevators moving people and goods vertically over long distances. As structures evolved from masonry foundations to steel construction, elevators evolved from geared to gearless and machine room to machine room-less traction systems. All of these advancements allowed elevators to go longer distances while moving passengers at greater speeds.

However, an increase in building height also meant an increase in the amount of people being transported. More people meant more elevators and this, along with the amount of cabling and horsepower requirements of super tall buildings, started to result in inefficiencies. The amount of floor space required for mobility started to limit the amount of people that could be moved. In addition, the amount of mass that had to be moved required very large motors and machines, and the length of cabling to suspend and move elevators started to become an engineering issue as well.

Since 2000, the number of high-rise buildings has increased significantly, as the current trend is building upward rather than outward. It is estimated most of the world population will live and work in cities by 2050, putting significant demands on building transportation systems. Industry has tried to compensate for taller buildings by running a faster elevator car, but the issue of pedestrian congestion remains, as buildings can only run a single cabin up and down the same hoistway.

Despite unprecedented tall building development, vertical transportation has hit a ceiling, and the elevator needs to be reimagined.

A DIFFERENT APPROACH

Elevator companies began examining ways to improve pedestrian movement and wait times in the growing number of high-rise structures, but many kept designing options that often just led them back to the drawing board. The goal itself was simple—figure out how to utilize multiple cars within one hoistway—but every solution was one big, tangled mess.

Ultimately, an elevator system had to be created that eliminated ropes altogether, a concept so far-fetched that many industry experts scoffed at the idea of ropeless elevators, believing it could only actually take flight in the fictional cinematic world of Willy Wonka & the Chocolate Factory. But, some 40 years after Willy Wonka and Charlie Bucket rode in a Wonkavator that could go "sideways and slantways and longways and backways," the ropeless elevator would reappear—in the real world.

The world’s first and only ropeless and sideways-moving elevator harnesses the power of linear motor technology to move multiple cars in a single shaft vertically and horizontally.

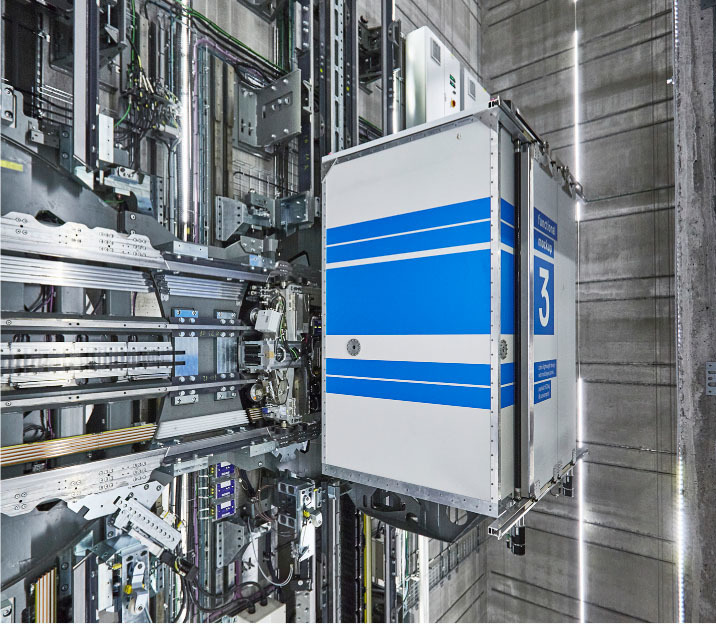

Under development for more than a decade, thyssenkrupp has debuted the world’s first and only ropeless and sideways-moving elevator, the MULTI system. This system harnesses the power of linear motor technology to move multiple cars in a single shaft vertically and horizontally. The system is inspired by the high-speed Transrapid monorail train, which utilizes magnetic levitation, or "maglev," technology. On the ropeless system, there is a stack of permanent magnets on the car. On the hoistway or guiding path from the car, there is a stack of electric coils with frequency drives that pulse and turn those coils on and off to move the car in any direction desired.

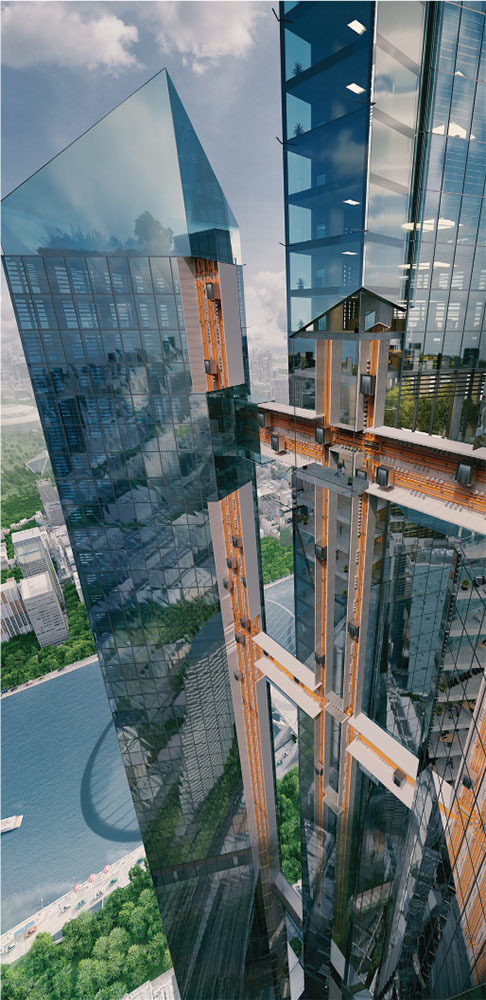

With a ropeless and sideways-moving elevator, architects and developers no longer need to be restricted in their building designs by concerns over elevator shaft height and vertical alignment.

Instead of one cabin per shaft moving up and down, the elevator system allows multiple cabins to operate in a continuous loop. Not only does this type of system increase a building’s usable area by up to 25 percent, adding rentable and leasable space, but it has a higher transport capacity with reduced wait time for passengers. It also runs at a comfortable speed of 1,000 to 1,400 feet per minute, ensuring a safe, smooth ride without the physical complications commonly associated with the fastest-moving elevators.

With this new system, architects and developers no longer need to be restricted in their building designs by concerns over elevator shaft height and vertical alignment. In addition, the system can be scaled to meet changing building use because it’s a continuous hoistway with more cars that can be taken in and out as needed, which is not an option with traditional elevators. And, not only does a ropeless elevator system open up infinite vertical building design opportunities, but because of its ability to move horizontally at any angle, it also can manage the traffic in round, complex building designs.

AN ENERGY BOOST

This type of next-generation technology also has the ability to transform any building into an energy-efficient structure. Global energy demand will increase by up to 35 percent over the next 15 years, with cities accounting for two-thirds of this increase. In urban environments, buildings can be one of the biggest consumers of energy. Elevators, in particular, can consume as much as 10 percent of a building’s energy.

A ropeless and sideways-moving elevator system not only has the potential to revolutionize pedestrian movement in (and out of) buildings, it also will significantly alter how buildings consume energy. With multiple cabs running in a single shaft, the ropeless system minimizes an elevator’s footprint because it requires fewer shafts. It also requires dramatically lower peak power, reducing that by as much as 60 percent when compared to conventional elevator systems. When fewer cabs are needed during off-peak periods, they simply can be parked and their power turned off. This allows for better management of a building’s energy needs and reduces investment costs in the power supply infrastructure.

And, because it has individual linear motors specific to each cab and since it does not require traveling cables, the motor size does not need to change as travel distances increase. By incorporating a ropeless and sideways-moving elevator system, buildings are only using the necessary specific energy to move the cab and its contents rather than requiring the motor to move the entire mass of the system. The technology also has the ability to regain energy, buffer it in batteries and then send it back to the internal grid, helping to reduce overall energy consumption.

A ropeless and sideways moving elevator system not only has the potential to revolutionize pedestrian movement in (and out of) buildings, it also will significantly alter how buildings consume energy.

MOVING FORWARD

The first ropeless elevator system will be installed in Berlin by 2022 and it is set to make its U.S. debut shortly thereafter when the tallest elevator testing and qualification center in North America opens. While this type of system is ideal for high-rise buildings, it also can be implemented in other creative ways, such as at a ski resort or even in iconic, centuries-old buildings where a basic elevator system isn’t an option. In addition, the technology has important implications for physical accessibility: People with limited mobility may be able to travel farther throughout a building using these systems.

The ropeless elevator system just might be the most important technological advancement the elevator world has seen since the inception of the safety elevator 160 years ago. And, after earning prominent innovation and energy efficiency accolades over the past year, it seems the future of elevators and building design will finally soar to new heights.

ABOUT THE AUTHOR: Michael Cesarz is the CEO of MULTI at thyssenkrupp Elevator. Cesarz, a trained architect, is a specialist in innovative developments, garnering worldwide attention for designing such structures as the Meydan Mall in Istanbul, Turkey, as well as follow-up concepts for such buildings as The Edge in Amsterdam. Learn more at http://multi.thyssenkrupp-elevator.com.